In the realm of business, inventory management stands as a cornerstone of success, directly impacting profitability, customer satisfaction, and operational efficiency. Inventory software for business emerges as a game-changer, empowering organizations to overcome inventory challenges, optimize stock levels, and unlock a world of benefits.

With inventory software at the helm, businesses can bid farewell to the frustrations of stockouts, overstocking, and manual errors. It automates inventory tracking, provides real-time visibility, and streamlines processes, leading to improved accuracy, reduced costs, and enhanced efficiency.

Inventory Management Challenges

Inventory management is a critical aspect of business operations, but it can also be a complex and challenging task. Businesses of all sizes face a variety of inventory management challenges, including stockouts, overstocking, and manual errors.

Stockouts occur when a business runs out of a particular item, resulting in lost sales and customer dissatisfaction. Stockouts can be caused by a variety of factors, such as inaccurate inventory data, poor demand forecasting, or disruptions in the supply chain.

Overstocking occurs when a business has too much inventory on hand. This can lead to increased storage costs, product damage, and obsolescence. Overstocking can be caused by a variety of factors, such as inaccurate inventory data, poor demand forecasting, or excessive purchasing.

Manual errors are another common challenge in inventory management. These errors can occur during any stage of the inventory management process, from data entry to physical inventory counts. Manual errors can lead to inaccurate inventory data, which can then lead to stockouts or overstocking.

Overcoming Inventory Management Challenges

There are a number of ways to overcome the challenges of inventory management. These include:

- Using inventory management software to automate inventory processes and improve accuracy.

- Implementing a robust demand forecasting system to better predict customer demand.

- Establishing a safety stock level to buffer against stockouts.

- Conducting regular inventory audits to ensure accuracy.

- Training staff on proper inventory management procedures.

Benefits of Inventory Software

Inventory software is a powerful tool that can help businesses streamline their inventory management processes, improve accuracy, reduce costs, and enhance efficiency. By automating many of the tasks associated with inventory management, businesses can save time and money while improving their overall inventory accuracy.

Some of the specific benefits of using inventory software include:

Improved Accuracy

- Inventory software can help businesses improve the accuracy of their inventory records by providing real-time visibility into their inventory levels. This can help businesses avoid stockouts and overstocking, which can lead to lost sales and wasted money.

- Inventory software can also help businesses track inventory movements, which can help them identify and resolve any discrepancies in their inventory records.

Reduced Costs

- Inventory software can help businesses reduce costs by optimizing their inventory levels. By keeping track of inventory levels in real-time, businesses can avoid overstocking, which can lead to wasted money on inventory that is not needed.

- Inventory software can also help businesses reduce costs by automating many of the tasks associated with inventory management, such as order processing and inventory counting. This can free up employees to focus on other tasks, such as customer service or sales.

Enhanced Efficiency

- Inventory software can help businesses enhance efficiency by streamlining their inventory management processes. By automating many of the tasks associated with inventory management, businesses can save time and improve their overall efficiency.

- Inventory software can also help businesses improve their customer service by providing them with real-time visibility into their inventory levels. This can help businesses avoid stockouts and ensure that they can meet customer demand.

Features of Inventory Software

Inventory software provides a wide range of features to help businesses manage their inventory effectively. These features can be categorized into core features, advanced features, and add-ons.

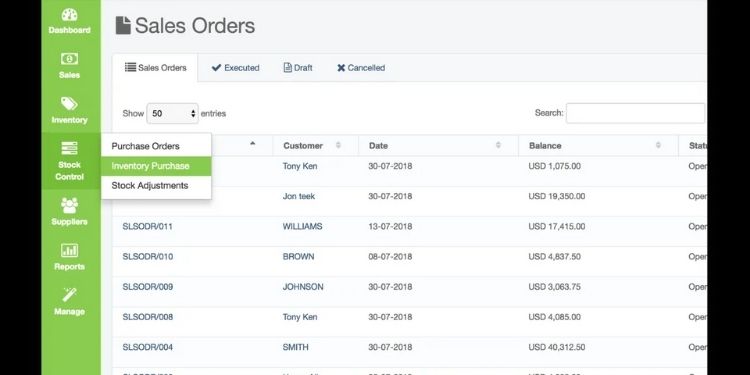

Core Features, Inventory software for business

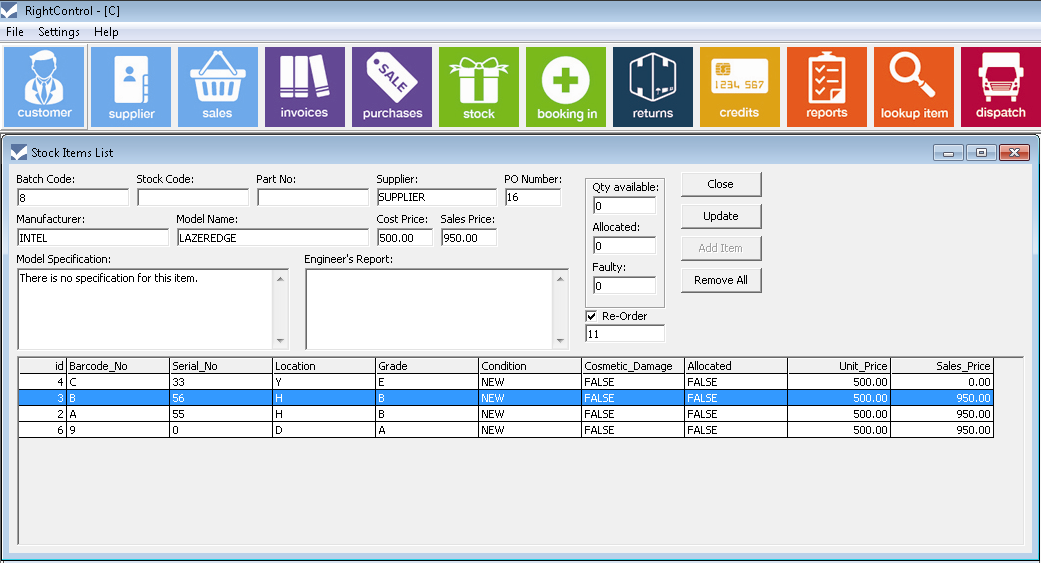

- Inventory tracking: Track inventory levels in real-time, including on-hand quantities, available quantities, and reorder points.

- Reporting: Generate reports on inventory levels, stock movements, and other key metrics.

- Integration with other business systems: Integrate with accounting, e-commerce, and other business systems to streamline operations.

Advanced Features

- Demand forecasting: Forecast future demand based on historical data and market trends.

- Multi-location management: Manage inventory across multiple locations, including warehouses, stores, and distribution centers.

- Warehouse management: Optimize warehouse operations, including receiving, putaway, and picking.

Add-Ons

- Barcode scanning: Use barcode scanners to automate inventory tracking and data entry.

- RFID tracking: Track inventory items using RFID tags for enhanced visibility and accuracy.

- Mobile apps: Access inventory data and perform tasks on the go using mobile devices.

Choosing the Right Inventory Software

Selecting the ideal inventory software requires a thorough evaluation process that aligns with your business’s unique requirements. Consider factors such as the size of your operation, the industry you operate in, and your budget constraints.

Factors to Consider

- Business Size: Smaller businesses may prioritize user-friendly software with limited features, while larger enterprises might seek comprehensive solutions with advanced capabilities.

- Industry: Specialized industries, such as healthcare or manufacturing, often require industry-specific software tailored to their unique inventory management needs.

- Budget: Software costs vary significantly, so determine a realistic budget before exploring options. Consider both upfront costs and ongoing expenses like maintenance and support.

Implementing Inventory Software

Implementing inventory software can streamline operations, improve accuracy, and save time. The process typically involves data migration, training, and ongoing support.

To ensure a smooth implementation, it’s crucial to plan thoroughly, communicate effectively, and involve stakeholders throughout the process.

Data Migration

Migrating data from an existing system to the new software is a critical step. Ensure data accuracy by verifying and cleaning it before migration.

- Identify all relevant data sources, including product information, inventory levels, and historical transactions.

- Establish a data mapping process to match fields between the old and new systems.

- Perform data cleansing to remove duplicates, correct errors, and ensure consistency.

- Conduct thorough data testing to validate accuracy and identify any issues.

Training

Training is essential for successful software adoption. Provide comprehensive training to all users, covering both basic and advanced functionalities.

- Develop a training plan that addresses different user roles and skill levels.

- Use a combination of hands-on demonstrations, documentation, and online resources.

- Encourage user participation and feedback to ensure understanding and engagement.

- Provide ongoing training and support as new features and updates are released.

Ongoing Support

Ongoing support is crucial to ensure the software continues to meet business needs and maximize its benefits.

- Establish a support system that includes technical assistance, documentation, and user forums.

- Monitor system performance regularly and address any issues promptly.

- Provide regular software updates and enhancements to maintain functionality and security.

- Foster a collaborative relationship with the software vendor for ongoing support and improvement.

Best Practices for Inventory Management: Inventory Software For Business

Inventory management best practices are essential for businesses to optimize stock levels, reduce costs, and improve customer satisfaction. These practices include implementing inventory control techniques, setting reorder points, and conducting regular inventory audits.

Inventory software can significantly support these best practices by automating many of the tasks involved and providing real-time data and insights.

Inventory Control Techniques

Inventory control techniques are strategies and methods used to manage inventory levels effectively. Common techniques include:

- First-in, first-out (FIFO): This method assumes that the oldest inventory is sold first.

- Last-in, first-out (LIFO): This method assumes that the newest inventory is sold first.

- Weighted average cost: This method calculates the average cost of inventory items based on their purchase prices and quantities.

Setting Reorder Points

Reorder points are the minimum inventory levels at which a new order should be placed. Setting appropriate reorder points is crucial to avoid stockouts and overstocking.

Inventory software can help businesses calculate reorder points based on historical data, demand forecasts, and lead times.

Conducting Regular Inventory Audits

Inventory audits involve physically counting and verifying inventory items to ensure accuracy. Regular audits help businesses identify discrepancies, reduce shrinkage, and improve inventory management processes.

Inventory software can streamline the audit process by providing real-time inventory data and enabling automated discrepancy reporting.

Case Studies and Success Stories

Inventory software has transformed the way businesses manage their inventory, leading to significant improvements in efficiency, cost savings, and customer satisfaction. Here are a few real-world examples of businesses that have successfully implemented inventory software:

Increased Sales and Customer Satisfaction

- Company A, a small online retailer, implemented an inventory management system that provided real-time inventory visibility. This enabled them to track stock levels accurately, avoid stockouts, and fulfill orders promptly. As a result, they experienced a 15% increase in sales and improved customer satisfaction by reducing the number of order cancellations due to out-of-stock items.

Reduced Inventory Costs and Waste

- Company B, a manufacturing company, implemented an inventory management system that optimized stock levels based on historical demand data. This helped them reduce excess inventory by 20%, freeing up capital and reducing storage costs. They also experienced a 10% reduction in inventory waste due to improved forecasting and demand planning.

Improved Warehouse Efficiency and Productivity

- Company C, a large warehouse distributor, implemented a warehouse management system that automated inventory tracking, picking, and packing processes. This led to a 25% increase in warehouse efficiency, reduced labor costs, and improved order accuracy. The system also provided real-time visibility into inventory levels, enabling the company to make informed decisions about inventory replenishment and distribution.

Future Trends in Inventory Management

The future of inventory management is bright, with new technologies and trends emerging that will help businesses to manage their inventory more efficiently and effectively. These trends include the use of artificial intelligence (AI) and the Internet of Things (IoT).

AI can be used to automate many of the tasks associated with inventory management, such as forecasting demand, optimizing stock levels, and generating reports. This can free up time for human employees to focus on more strategic tasks, such as developing new products and improving customer service.

IoT devices can be used to track the movement of inventory in real time. This information can be used to improve inventory accuracy, reduce waste, and prevent theft. IoT devices can also be used to monitor environmental conditions, such as temperature and humidity, which can affect the quality of inventory.

The impact of AI and IoT on inventory software

The use of AI and IoT is having a significant impact on inventory software. Inventory software vendors are now developing software that is specifically designed to take advantage of these technologies.

AI-powered inventory software can help businesses to:

- Forecast demand more accurately

- Optimize stock levels

- Generate reports automatically

- Identify trends and patterns

- Predict future inventory needs

IoT-enabled inventory software can help businesses to:

- Track the movement of inventory in real time

- Improve inventory accuracy

- Reduce waste

- Prevent theft

- Monitor environmental conditions

The use of AI and IoT is still in its early stages, but these technologies have the potential to revolutionize inventory management. Businesses that are able to adopt these technologies early will be well-positioned to succeed in the future.

Conclusive Thoughts

As the future of inventory management unfolds, businesses that embrace inventory software will stay ahead of the curve, harnessing the power of AI and IoT to further optimize their operations. By adopting best practices and leveraging the latest technologies, organizations can unlock the full potential of inventory software, driving growth, profitability, and customer satisfaction.

Clarifying Questions

What are the key features to look for in inventory software?

Inventory tracking, reporting, integration with other business systems, forecasting, and mobile access.

How can inventory software help businesses reduce costs?

By optimizing stock levels, reducing manual errors, and improving efficiency, inventory software can significantly reduce operating costs.

What are the benefits of using cloud-based inventory software?

Cloud-based inventory software offers real-time data access, scalability, and reduced IT maintenance costs.