Introducing the Business Inventory Management System (BIMS), an essential tool for businesses seeking to streamline their inventory processes and maximize efficiency. BIMS empowers businesses to gain real-time visibility, optimize stock levels, and enhance decision-making, ultimately driving profitability and customer satisfaction.

With its comprehensive features and seamless integration capabilities, BIMS transforms inventory management into a strategic advantage, enabling businesses to stay ahead in today’s competitive market.

Business Inventory Management System (BIMS) Overview

A Business Inventory Management System (BIMS) is a software solution that helps businesses track and manage their inventory levels. It provides real-time visibility into inventory levels, allowing businesses to make informed decisions about purchasing, production, and sales.

Implementing a BIMS can provide numerous benefits to businesses, including:

- Improved inventory accuracy

- Reduced inventory costs

- Increased sales

- Improved customer service

- Enhanced decision-making

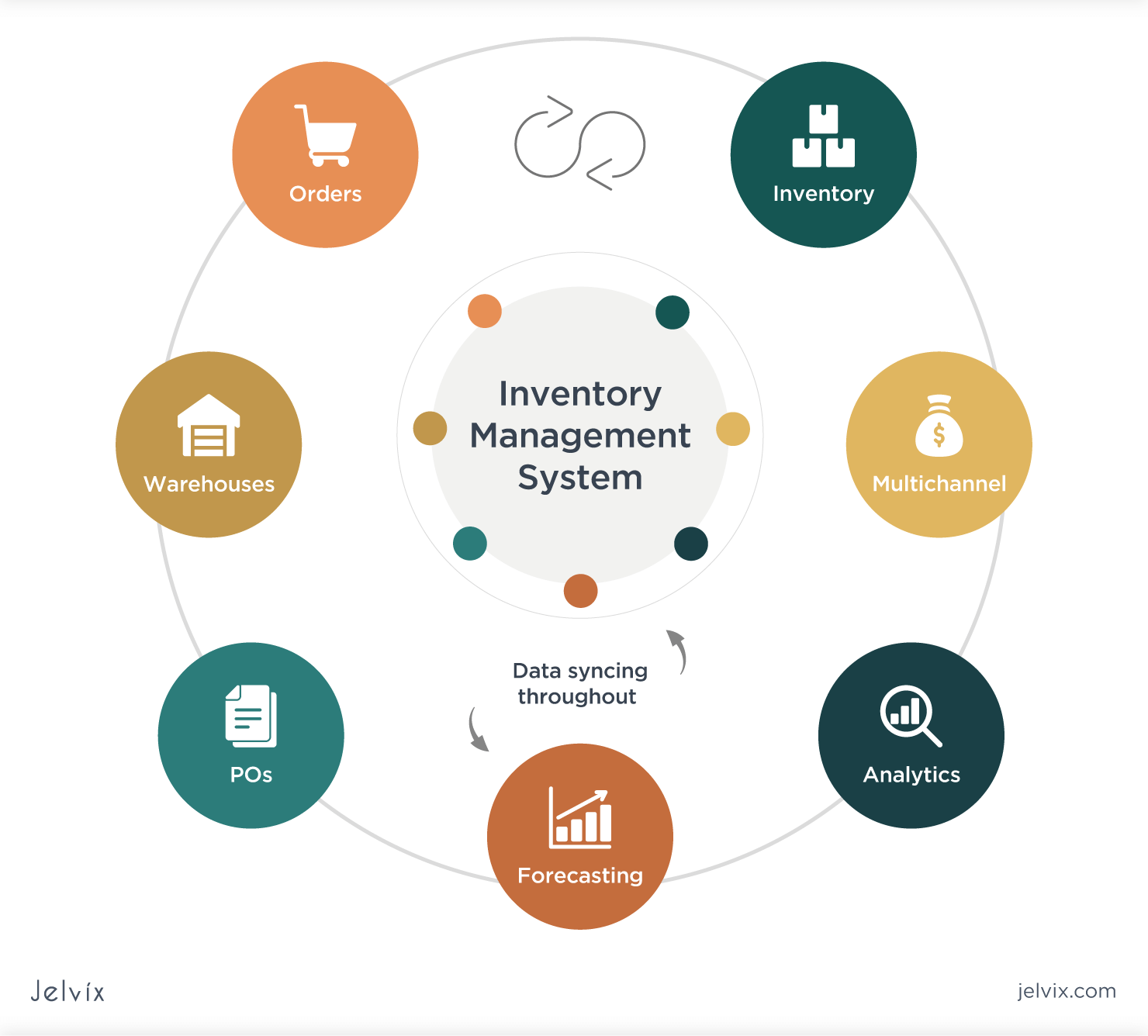

Key Components of a BIMS

A Business Inventory Management System (BIMS) is a software solution that helps businesses track and manage their inventory levels. BIMSs can be used to improve inventory accuracy, reduce costs, and improve customer service. The key components of a BIMS include:

- Inventory tracking:This component allows businesses to track the quantity and location of their inventory items.

- Order management:This component allows businesses to manage the process of ordering inventory items from suppliers.

- Warehouse management:This component allows businesses to manage the process of receiving, storing, and shipping inventory items.

- Reporting:This component allows businesses to generate reports on their inventory levels, order history, and warehouse activity.

These components work together to provide businesses with a comprehensive view of their inventory. This information can be used to make informed decisions about inventory levels, ordering, and warehousing. BIMSs can also help businesses to improve their customer service by ensuring that they have the right products in stock when customers need them.

Types of BIMS

Business inventory management systems (BIMS) can be categorized into various types based on their features and functionalities. Each type offers unique advantages and disadvantages, catering to specific business needs and requirements.

The following are some common types of BIMS:

Cloud-Based BIMS

- Hosted on remote servers, accessible via the internet.

- Advantages:

- Scalability and flexibility

- Lower upfront costs

- Automatic updates and maintenance

- Disadvantages:

- Reliance on internet connectivity

- Security concerns

- Limited customization options

On-Premises BIMS

- Installed and managed on local servers within the business premises.

- Advantages:

- Greater control over data and security

- Extensive customization options

- Higher upfront costs

- Disadvantages:

- Maintenance and updates require in-house IT resources

- Limited scalability

- Higher hardware and software costs

Perpetual License BIMS, Business inventory management system

- Purchased once and used indefinitely.

- Advantages:

- No ongoing subscription fees

- Full ownership and control

- Higher upfront costs

- Disadvantages:

- Manual updates and maintenance

- Limited support

- May become outdated over time

Subscription-Based BIMS

- Paid on a monthly or annual basis.

- Advantages:

- Lower upfront costs

- Automatic updates and support

- Scalability and flexibility

- Disadvantages:

- Ongoing subscription fees

- Limited ownership

- May have usage restrictions

BIMS Implementation

Implementing a Business Inventory Management System (BIMS) involves several key steps, including planning, selection, configuration, testing, and deployment. Each step plays a crucial role in ensuring the successful implementation and utilization of the BIMS.

Effective BIMS implementation requires careful planning and preparation. This includes defining the project scope, identifying stakeholders, establishing timelines, and securing necessary resources. Organizations must thoroughly assess their inventory management needs, processes, and existing infrastructure to determine the most suitable BIMS solution.

Challenges of BIMS Implementation

- Data Migration:Transferring existing inventory data from legacy systems or manual records to the new BIMS can be a complex and time-consuming process, requiring careful planning and data validation.

- Integration with Existing Systems:BIMS must seamlessly integrate with other enterprise systems, such as ERP, accounting, and supply chain management systems, to ensure data accuracy and process efficiency.

- User Adoption and Training:Ensuring that users are adequately trained and comfortable with the new BIMS is essential for successful implementation. Resistance to change and lack of user buy-in can hinder the effectiveness of the system.

- Scalability and Flexibility:BIMS should be scalable to accommodate future growth and adaptable to changing business requirements, such as new product lines or inventory tracking methods.

- Data Security and Compliance:Maintaining data security and adhering to regulatory compliance requirements are critical considerations during BIMS implementation to protect sensitive inventory information.

Best Practices for BIMS Implementation

- Phased Approach:Implementing BIMS in phases allows organizations to minimize disruption and gradually transition to the new system while maintaining business continuity.

- Data Cleansing and Validation:Ensuring data accuracy and completeness before migration is essential to avoid errors and maintain data integrity within the BIMS.

- Thorough Testing:Extensive testing of the BIMS before deployment helps identify and resolve any potential issues, ensuring smooth system operation and minimizing post-implementation disruptions.

- User Involvement and Training:Engaging users throughout the implementation process and providing comprehensive training empowers them to effectively utilize the BIMS and realize its full potential.

- Continuous Improvement:BIMS should be continuously monitored and evaluated to identify areas for improvement, ensuring alignment with evolving business needs and maximizing system effectiveness.

BIMS Integration

Integrating a BIMS with other business systems, such as Enterprise Resource Planning (ERP) and Customer Relationship Management (CRM), streamlines operations and enhances data accuracy.

ERP systems manage financial, supply chain, and human resources data, while CRM systems track customer interactions and sales opportunities. By integrating these systems with a BIMS, businesses can:

Data Synchronization

- Eliminate manual data entry and reduce errors by automatically synchronizing inventory levels, product information, and customer orders across systems.

- Ensure consistency and accuracy of data, leading to better decision-making and improved customer service.

Automated Processes

- Automate inventory replenishment processes based on real-time demand data from ERP and CRM systems.

- Trigger automatic notifications when inventory levels reach critical thresholds, preventing stockouts and ensuring customer satisfaction.

Improved Visibility

- Provide a comprehensive view of inventory across different locations and channels, enabling better inventory planning and forecasting.

- Track inventory movements and transactions in real-time, improving accountability and reducing shrinkage.

Considerations for Integration

- Data compatibility:Ensure that the data structures and formats of the BIMS and other systems are compatible for seamless integration.

- System availability:Consider the availability and reliability of the integrated systems to avoid disruptions in inventory management processes.

- Security:Implement robust security measures to protect sensitive inventory and customer data during integration and data exchange.

BIMS Analytics and Reporting: Business Inventory Management System

Inventory analytics and reporting are crucial for optimizing inventory management and decision-making. They provide insights into inventory performance, help identify areas for improvement, and enable businesses to stay ahead of potential issues.

Key metrics and KPIs for monitoring inventory performance include:

- Inventory turnover ratio: Measures the number of times inventory is sold and replaced during a specific period.

- Days inventory outstanding (DIO): Indicates the average number of days inventory is held before being sold.

- Stockout rate: Measures the percentage of customer orders that cannot be fulfilled due to stock unavailability.

- Inventory carrying costs: The total cost of holding inventory, including storage, insurance, and handling.

- Inventory shrinkage: The loss of inventory due to theft, damage, or obsolescence.

Inventory Forecasting

Inventory forecasting is a critical aspect of inventory management. It involves predicting future demand to ensure optimal inventory levels and avoid stockouts or overstocking.

Inventory Optimization

Inventory optimization aims to balance inventory levels to meet customer demand while minimizing costs. It involves techniques such as safety stock calculation, lead time management, and demand forecasting.

Emerging Trends in BIMS

The realm of Business Inventory Management Systems (BIMS) is constantly evolving, with cutting-edge technologies and advancements shaping its future. These trends are revolutionizing how businesses manage their inventory, enhancing efficiency, accuracy, and overall supply chain performance.

One notable trend is the integration of artificial intelligence (AI) and machine learning (ML) into BIMS. AI algorithms can analyze vast amounts of data to identify patterns, forecast demand, and optimize inventory levels. This enables businesses to make data-driven decisions, reduce waste, and improve customer service.

Cloud-Based BIMS

The adoption of cloud-based BIMS is another significant trend. Cloud-based systems offer scalability, flexibility, and accessibility from anywhere with an internet connection. Businesses can leverage cloud-based BIMS to streamline their inventory management processes, collaborate with suppliers and customers, and gain real-time visibility into their inventory levels.

Internet of Things (IoT) Integration

The integration of IoT devices into BIMS is also gaining momentum. IoT sensors can monitor inventory levels, track product movement, and provide real-time updates. This data can be used to automate inventory replenishment, improve warehouse operations, and enhance supply chain visibility.

Predictive Analytics

Predictive analytics is becoming increasingly important in BIMS. Advanced algorithms can analyze historical data and identify trends to predict future inventory needs. This enables businesses to anticipate demand fluctuations, optimize inventory levels, and avoid stockouts.

Sustainability and Environmental Considerations

Sustainability and environmental considerations are also shaping the future of BIMS. Businesses are increasingly adopting eco-friendly inventory management practices to reduce waste and minimize their environmental impact. BIMS can help track and monitor inventory levels, identify slow-moving items, and implement strategies to reduce waste and optimize inventory turnover.

BIMS Case Studies

Businesses of all sizes and industries can benefit from implementing a BIMS. Here are some real-world examples of successful BIMS implementations:

Example 1:A large manufacturing company implemented a BIMS to track inventory levels across its multiple warehouses. The system helped the company to reduce inventory costs by 15% and improve customer service levels by 20%. The company was able to achieve these benefits by using the BIMS to:

- Improve inventory visibility

- Optimize inventory levels

- Reduce inventory shrinkage

- Improve customer service levels

Example 2:A retail chain implemented a BIMS to manage inventory levels at its stores. The system helped the company to reduce inventory costs by 10% and improve sales by 5%. The company was able to achieve these benefits by using the BIMS to:

- Improve inventory visibility

- Optimize inventory levels

- Reduce inventory shrinkage

- Improve customer service levels

These are just two examples of how businesses can benefit from implementing a BIMS. By using a BIMS, businesses can improve inventory visibility, optimize inventory levels, reduce inventory shrinkage, and improve customer service levels.

End of Discussion

In conclusion, BIMS is a transformative solution that empowers businesses to take control of their inventory, reduce costs, and enhance customer service. By embracing the power of BIMS, businesses can unlock the full potential of their inventory, driving growth and success in the digital age.

Common Queries

What are the key benefits of implementing a BIMS?

BIMS offers numerous benefits, including improved inventory accuracy, reduced stockouts, optimized stock levels, enhanced customer service, and cost savings.

How does a BIMS integrate with other business systems?

BIMS can seamlessly integrate with ERP, CRM, and other business systems, enabling real-time data sharing and streamlining business processes.

What are the emerging trends in BIMS technology?

BIMS technology is constantly evolving, with trends such as cloud-based solutions, artificial intelligence, and predictive analytics gaining prominence.