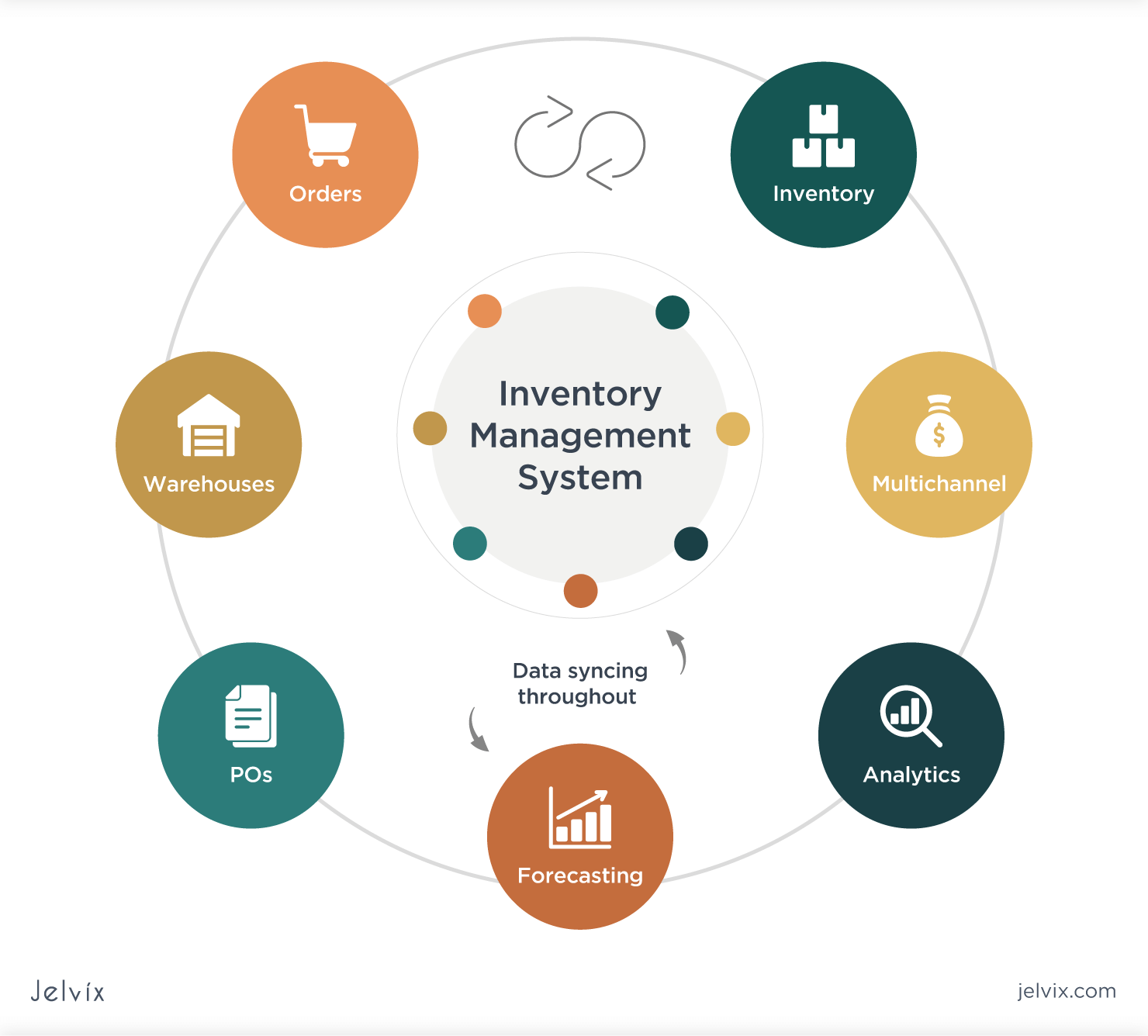

Inventory systems for businesses are essential tools that can help streamline operations, reduce costs, and improve customer satisfaction. By providing real-time inventory tracking, forecasting, and reporting, these systems empower businesses to make informed decisions about their inventory levels, ensuring they have the right products in stock at the right time.

In this comprehensive guide, we will delve into the world of inventory management systems, exploring their benefits, key features, challenges, and best practices. We will also discuss emerging trends in inventory management and how they are shaping the future of business operations.

Benefits of Using Inventory Management Systems: Inventory Systems For Businesses

Inventory management systems (IMS) provide numerous benefits to businesses of all sizes. By automating and streamlining inventory processes, businesses can reduce costs, improve efficiency, and enhance customer satisfaction.

Impact on Key Metrics

- Inventory Turnover: IMS helps businesses optimize their inventory levels, reducing the risk of overstocking or understocking. This results in higher inventory turnover, which means businesses can sell their inventory faster and generate more revenue.

- Carrying Costs: IMS helps businesses reduce carrying costs by minimizing the amount of inventory they hold. This can free up capital for other investments and reduce the cost of storage, insurance, and other expenses associated with holding inventory.

- Customer Satisfaction: IMS helps businesses improve customer satisfaction by ensuring that they have the products they need in stock when they need them. This reduces the risk of lost sales and unhappy customers.

Case Studies

Numerous businesses have successfully implemented IMS and experienced significant benefits. For example, Amazon uses an advanced IMS to manage its vast inventory of millions of products. This system allows Amazon to optimize its inventory levels, reduce carrying costs, and improve customer satisfaction.

Challenges of Implementing Inventory Management Systems

Implementing inventory management systems can bring significant benefits to businesses, but it also comes with its own set of challenges. Understanding and addressing these challenges is crucial for ensuring a successful implementation and maximizing the potential benefits.

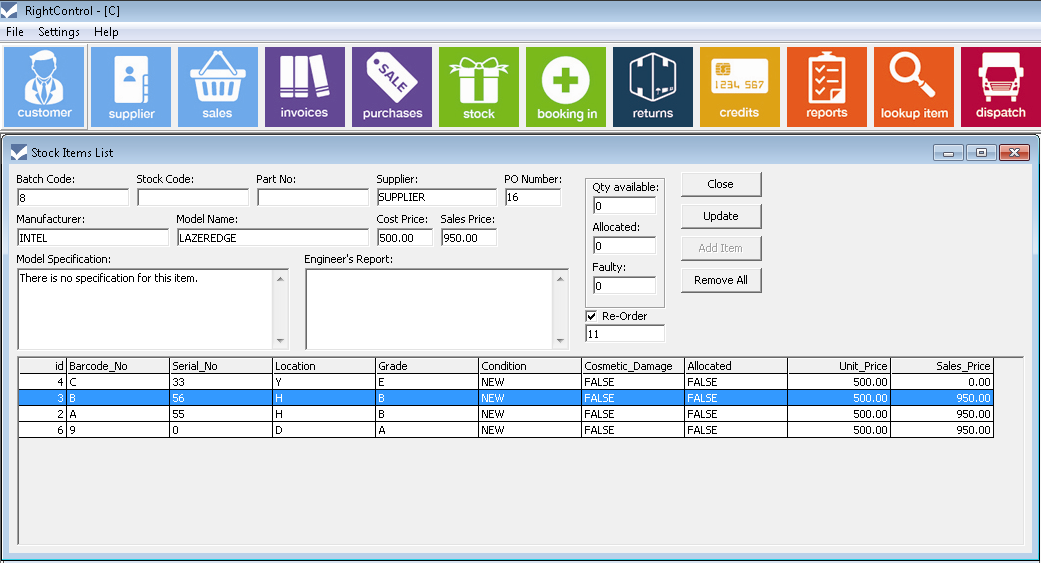

Data Integration

Integrating inventory data from multiple sources, such as point-of-sale systems, warehouses, and suppliers, can be a significant challenge. Data inconsistencies, lack of standardization, and manual data entry errors can lead to inaccurate inventory records and poor decision-making.

User Adoption, Inventory systems for businesses

Gaining user adoption and ensuring employees embrace the new system is essential for successful implementation. Resistance to change, lack of training, and poor communication can hinder user adoption, leading to the underutilization of the system.

System Maintenance

Inventory management systems require ongoing maintenance and updates to ensure optimal performance and security. Neglecting system maintenance can result in performance issues, data loss, and vulnerabilities that can compromise the system’s effectiveness.

Best Practices for Inventory Management

Establish best practices for inventory management to maximize the effectiveness of inventory management systems. By implementing these practices, businesses can optimize inventory levels, minimize waste, and improve overall operational efficiency.

Inventory Control

Inventory control involves establishing processes to maintain accurate and up-to-date inventory records. This includes:

- Regular inventory counts

- Tracking inventory movements

- Setting reorder points and safety stock levels

Cycle Counting

Cycle counting is a process of physically verifying inventory counts at regular intervals throughout the year. This helps to identify and correct any discrepancies between the physical inventory and the inventory records, ensuring accuracy and preventing overstocking or understocking.

Safety Stock Management

Safety stock refers to the extra inventory kept on hand to buffer against unexpected demand fluctuations or supply chain disruptions. Determining the appropriate safety stock level involves considering factors such as lead times, demand variability, and the importance of the item.

Tips for Optimizing Inventory Levels

- Use inventory management software to track inventory levels and automate processes.

- Implement just-in-time (JIT) inventory management to minimize inventory holding costs.

- Conduct regular inventory audits to identify obsolete or slow-moving items.

- Establish vendor relationships and negotiate favorable terms for timely deliveries.

- Use forecasting techniques to predict future demand and adjust inventory levels accordingly.

Strategies for Minimizing Waste

- Implement a first-in, first-out (FIFO) inventory management system to prevent older inventory from becoming obsolete.

- Use inventory management software to track expiration dates and prevent spoilage.

- Establish a system for handling damaged or returned goods to minimize losses.

- Consider implementing a vendor-managed inventory (VMI) system to optimize inventory levels and reduce waste.

Future Trends in Inventory Management

The future of inventory management is being shaped by emerging technologies such as artificial intelligence (AI) and machine learning (ML). These technologies are helping businesses achieve greater efficiency and accuracy in their inventory management processes.

One of the most significant trends in inventory management is the use of AI to automate tasks. AI-powered systems can be used to track inventory levels, forecast demand, and generate purchase orders. This can free up employees to focus on more strategic tasks, such as developing new products or improving customer service.

ML is also being used to improve the accuracy of inventory management systems. ML algorithms can be trained on historical data to identify patterns and trends. This information can then be used to make more accurate predictions about future demand. As a result, businesses can reduce their inventory levels and improve their cash flow.

Challenges and Opportunities

While AI and ML offer significant benefits for inventory management, there are also some challenges to consider. One challenge is the cost of implementing these technologies. AI and ML systems can be expensive to purchase and maintain. Another challenge is the need for skilled workers to manage these systems. Businesses will need to invest in training their employees or hiring new staff with the necessary skills.

Despite these challenges, AI and ML offer significant opportunities for businesses to improve their inventory management processes. Businesses that are able to successfully implement these technologies will be well-positioned to compete in the future.

Closing Notes

Inventory management systems are a valuable asset for businesses of all sizes, providing numerous benefits and helping them overcome challenges. By implementing these systems effectively, businesses can gain a competitive edge, improve their bottom line, and enhance customer satisfaction. As technology continues to evolve, inventory management systems will become even more sophisticated, enabling businesses to achieve even greater efficiency and accuracy in their operations.

Frequently Asked Questions

What are the benefits of using inventory management systems?

Inventory management systems offer numerous benefits, including reduced inventory costs, improved customer satisfaction, increased sales, and enhanced operational efficiency.

What are the key features of inventory management systems?

Key features of inventory management systems include real-time inventory tracking, forecasting, reporting, and integration with other business systems.

What are the challenges of implementing inventory management systems?

Common challenges include data integration, user adoption, and system maintenance. However, these challenges can be overcome with proper planning and execution.