Keeping inventory for small business – In the competitive landscape of small business, keeping inventory is not just a task but a strategic advantage. This comprehensive guide delves into the significance and challenges of inventory management, empowering you with practical methods and expert tips to optimize your stock, minimize costs, and maximize profits.

With clear explanations and actionable insights, this guide provides a roadmap for small businesses to navigate the complexities of inventory management, ensuring accuracy, efficiency, and a competitive edge.

Inventory Management for Small Businesses

Effective inventory management is crucial for small businesses as it helps them optimize their resources, reduce costs, and improve customer satisfaction. It involves tracking the quantity and value of goods in stock, ensuring availability, and preventing overstocking or shortages.

Challenges of Inventory Management for Small Businesses

Small businesses often face challenges in inventory management due to limited resources, space constraints, and lack of specialized staff. They may struggle with:

- Inaccurate inventory records: Manual inventory tracking can lead to errors, resulting in overstocking or understocking.

- Limited storage space: Small businesses may have limited space to store inventory, making it difficult to maintain optimal stock levels.

- Lack of inventory management software: Manual inventory management is time-consuming and inefficient, especially as businesses grow.

- Cash flow constraints: Small businesses may have limited cash flow to invest in inventory, making it challenging to maintain adequate stock levels.

Methods for Keeping Inventory

Choosing the right inventory management method is crucial for small businesses. Here’s a comparison of different methods to help you make an informed decision:

Manual Inventory Management

Advantages:

- Low cost and easy to implement.

- Suitable for small businesses with a limited number of items.

Disadvantages:

- Prone to errors due to human input.

- Time-consuming and inefficient for businesses with a large inventory.

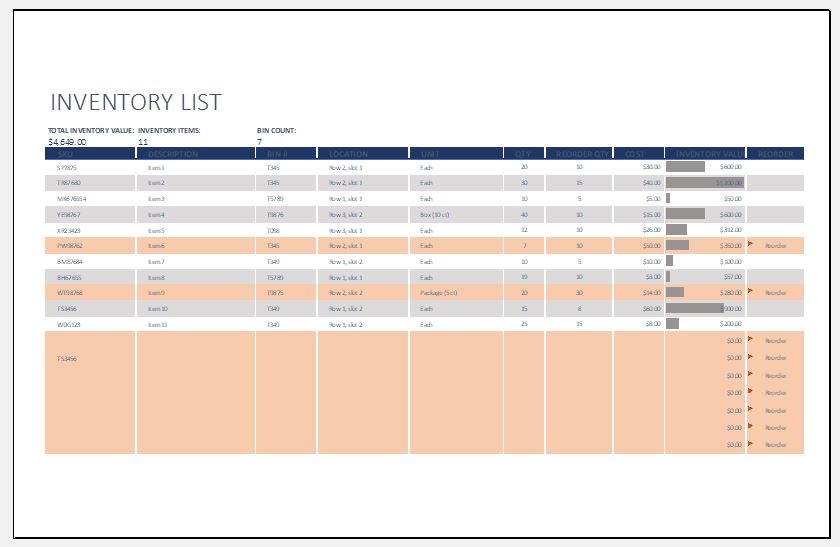

Spreadsheet Inventory Management

Advantages:

- More organized and efficient than manual methods.

- Allows for basic inventory tracking and reporting.

- Relatively low cost compared to inventory management software.

Disadvantages:

- Still prone to errors due to manual data entry.

- Limited functionality compared to dedicated inventory management software.

- Can become complex and unwieldy as inventory grows.

Inventory Management Software, Keeping inventory for small business

Advantages:

- Automates inventory tracking, reducing errors.

- Provides real-time inventory visibility and reporting.

- Supports advanced features like barcode scanning, order management, and forecasting.

Disadvantages:

- Can be expensive for small businesses.

- Requires proper implementation and training to use effectively.

Inventory Optimization

Inventory optimization is the process of determining the optimal levels of inventory to hold to meet customer demand while minimizing costs. It involves balancing the need to have enough inventory on hand to meet demand with the cost of holding that inventory.

There are a number of factors to consider when optimizing inventory levels, including:

- Demand: The rate at which customers are expected to purchase a product.

- Lead time: The time it takes to receive inventory from a supplier.

- Safety stock: The amount of inventory held in reserve to buffer against unexpected fluctuations in demand or lead time.

- Holding costs: The cost of holding inventory, including storage, insurance, and obsolescence.

Tips for Optimizing Inventory Levels

There are a number of tips that small businesses can follow to optimize their inventory levels and minimize costs:

- Use a perpetual inventory system: A perpetual inventory system tracks inventory levels in real time, which allows businesses to have a more accurate picture of their inventory on hand. This can help businesses avoid overstocking or understocking.

- Use a safety stock formula: A safety stock formula can help businesses determine the optimal level of safety stock to hold. This can help businesses avoid stockouts while minimizing the cost of holding inventory.

- Use a reorder point system: A reorder point system can help businesses determine when to reorder inventory. This can help businesses avoid running out of stock while minimizing the cost of holding inventory.

- Use a just-in-time (JIT) inventory system: A JIT inventory system is designed to minimize the amount of inventory held on hand. This can help businesses reduce their holding costs.

- Use a vendor-managed inventory (VMI) system: A VMI system allows businesses to outsource their inventory management to a supplier. This can help businesses reduce their inventory costs and improve their inventory accuracy.

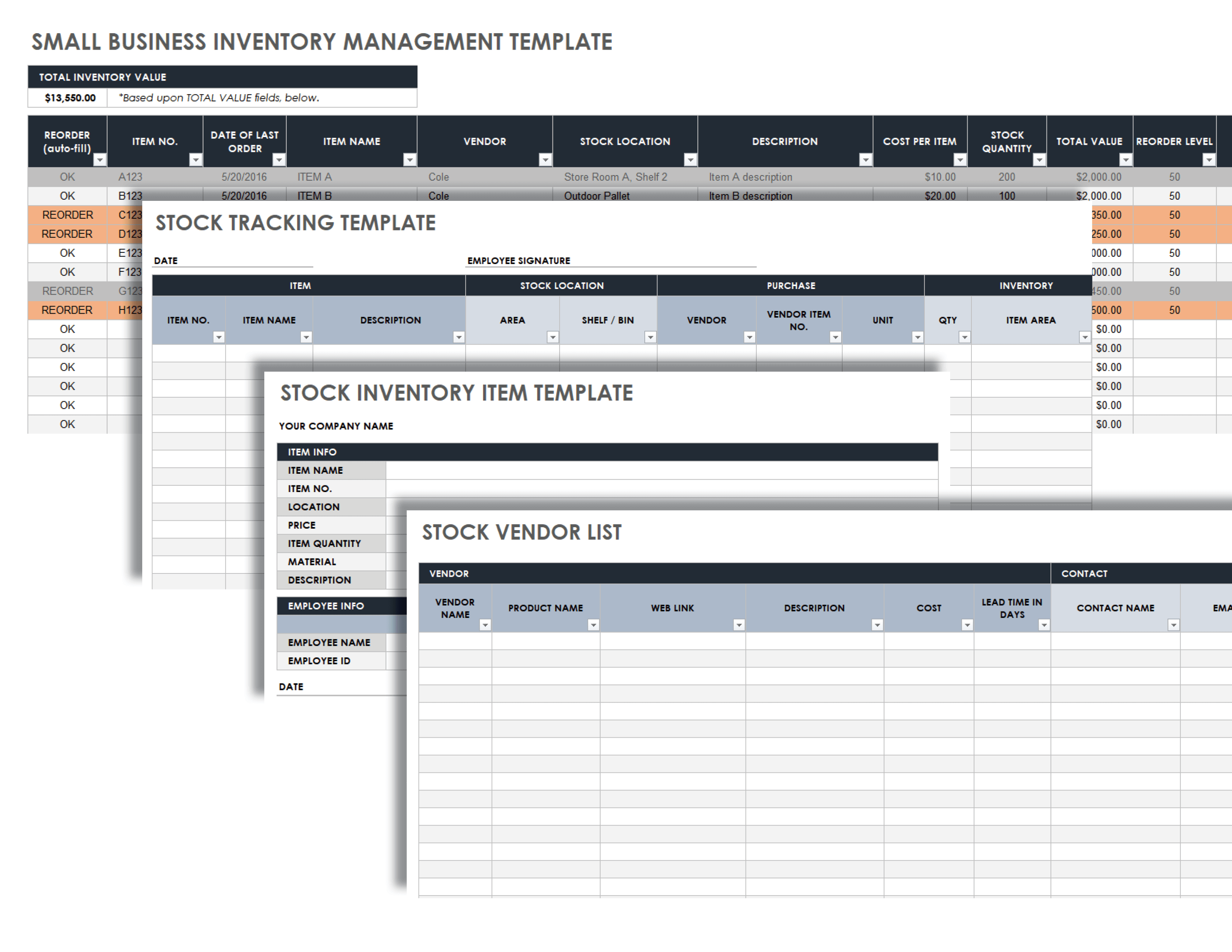

Technology for Inventory Management: Keeping Inventory For Small Business

![]()

Inventory management software is a valuable tool for small businesses to streamline their inventory operations. It can help businesses track inventory levels, automate ordering, and optimize inventory levels.

Here are some of the benefits of using inventory management software:

- Improved accuracy: Inventory management software can help businesses track inventory levels more accurately, reducing the risk of stockouts and overstocking.

- Increased efficiency: Inventory management software can automate many of the tasks associated with inventory management, such as ordering and tracking inventory levels, freeing up time for other tasks.

- Reduced costs: Inventory management software can help businesses reduce costs by optimizing inventory levels and reducing the risk of stockouts and overstocking.

- Improved customer service: Inventory management software can help businesses improve customer service by providing real-time information on inventory levels, so that customers can be informed about the availability of products.

Comparison of Inventory Management Software Solutions

There are a number of different inventory management software solutions available on the market. Here is a table comparing four of the most popular solutions:

| Feature | QuickBooks Online | Zoho Inventory | Shopify | Square |

|---|---|---|---|---|

| Inventory tracking | Yes | Yes | Yes | Yes |

| Order management | Yes | Yes | Yes | Yes |

| Warehouse management | No | Yes | Yes | Yes |

| Reporting | Yes | Yes | Yes | Yes |

| Pricing | Starting at $25/month | Starting at $49/month | Starting at $29/month | Starting at $60/month |

| User reviews | 4.5/5 stars on Trustpilot | 4.7/5 stars on Trustpilot | 4.6/5 stars on Trustpilot | 4.4/5 stars on Trustpilot |

Best Practices for Small Business Inventory Management

Efficient and accurate inventory management is crucial for the success of any small business. By avoiding common mistakes and implementing best practices, businesses can optimize their inventory levels, reduce costs, and improve customer satisfaction.

Common Mistakes to Avoid

- Overstocking: Holding excessive inventory can tie up capital, lead to spoilage or obsolescence, and increase storage costs.

- Understocking: Not having enough inventory can result in lost sales, dissatisfied customers, and damage to the business’s reputation.

- Inaccurate inventory records: Errors in inventory tracking can lead to incorrect ordering decisions, overstocking or understocking, and financial discrepancies.

- Lack of inventory tracking system: Manual inventory tracking methods can be time-consuming, error-prone, and inefficient.

- Poor inventory organization: Disorganized inventory can make it difficult to locate items, track stock levels, and manage inventory efficiently.

Best Practices for Efficient and Accurate Inventory Management

To optimize inventory management, small businesses should consider the following best practices:

- Establish a clear inventory policy: Define clear guidelines for inventory levels, ordering procedures, and stock management.

- Implement an inventory management system: Utilize technology to automate inventory tracking, optimize ordering, and generate reports.

- Conduct regular inventory audits: Regularly verify inventory levels against physical stock to identify discrepancies and ensure accuracy.

- Use inventory forecasting techniques: Forecast future demand to determine optimal inventory levels and avoid overstocking or understocking.

- Optimize inventory turnover: Track inventory turnover to identify slow-moving items and consider reducing stock levels or discontinuing those items.

- Establish vendor relationships: Build strong relationships with suppliers to ensure reliable delivery, negotiate favorable terms, and reduce lead times.

Conclusion

By embracing the strategies and best practices Artikeld in this guide, small businesses can transform their inventory management into a profit-generating asset. With optimized stock levels, reduced waste, and enhanced customer satisfaction, you can unlock the full potential of your business and drive success.

FAQ Overview

What are the key challenges of inventory management for small businesses?

Small businesses often face challenges such as limited resources, space constraints, and fluctuating demand, making inventory management complex.

How can inventory optimization benefit my small business?

Inventory optimization helps minimize carrying costs, reduce waste, improve cash flow, and enhance customer service levels.

What are the best practices for efficient inventory management?

Establish clear inventory policies, implement regular stock audits, use inventory management software, and train staff on proper inventory handling.